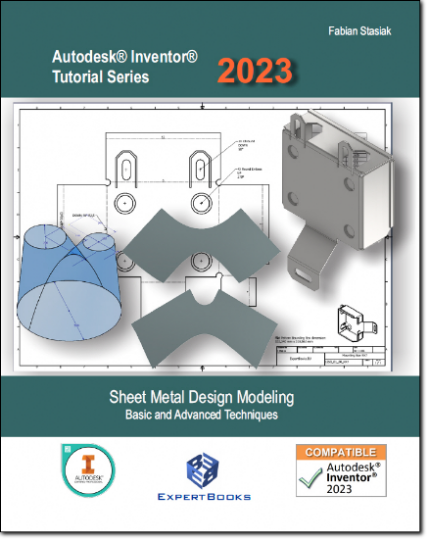

Autodesk Inventor 2023 Tutorial Series. Sheet Metal Design

Books

Title:

Sheet Metal Design Modeling

Basic and Advanced Techniques

Autodesk Inventor 2023 Tutorial Series

Publication Date: 2022-08

ISBN: 9798849303994

Page Count: 172

Binding Type: US Trade Paper

Trim Size: 8" x 10"

Language: English

Color: Black and White

Language: English

Price: $ 25.00

Sheet Metal Design Modeling

This tutorial is intended for people who are familiar with the basics of working with Autodesk Inventor and now want to learn all aspects of sheet metal design in Autodesk Inventor. The manual is divided into two main parts.

Basic techniques for creating sheet metal parts

In the first part, you will learn how to configure the Inventor Sheet Metal Environment and complete a number of tutorials to illustrate the use of specific Inventor tools specifically for sheet metal design, unfolding, saving DXF files, and creating sheet metal specific drawing documentation.

Advanced techniques for creating sheetmetal parts

In the second part of this tutorial, you will learn about the tools and techniques that go beyond the sheet metal design module's tools to help you design more complex sheet metal parts. It will show the application of selected solid modeling tools, the use of surface modeling and the multi-body technique that facilitate the design of various types of sheet metal parts and obtaining the flat pattern of the parts.

And…

To complete all the exercises, you need a set of exercise files that must be downloaded and unpacked to the default location before you start working with the book.

Selected illustrations from the e-book

Table of Contents

Sheet metal parts. The basics

Sheet metal stylesSheet Metal RuleSheet Metal UnfoldLinear K FactorBend TableCustom Equation

Parameters of the sheet metal modelFlat Pattern DXF file for a cutting machineSheet metal modeling environment

Preparation for the exercises

Set the project file for exercisesExercise 1 Configuration of styles and template for sheet metal partsExercise 2 Drawing template modification. Sheet thickness in title block

Basic techniques for creating sheet metal parts

Exercise 3 Flanges and mirror copy. Sheet metal wheel supportExercise 4 Flanges and corners. Sheet metal boxExercise 5 Contour flange around the edge. Sheet metal doorExercise 6 Contour Flange and Contour RollExercise 7 Bend, local unfolds and refolds, cuts. Mounting Box IExercise 8 Punch tool, bend orders. Mounting Box IIExercise 9 Text marking on the flat pattern. Creating a DXF fileExercise 10 Bending along the line. BracketExercise 11 Rectangle to Oval transitionExercise 12 A drawing of a sheet metal part containing a flat patternExercise 13 Flat Pattern area and thickness in the assembly drawingExercise 14 iFeature in sheet metal parts. Embossing

Advanced techniques for creating sheetmetal parts

Exercise 15 Standard tools in modeling sheet metal parts. Sleeve with a lockExercise 16 Multi-body technique. A sheet metal tunnel made of two partsExercise 17 Multi-body technique. Various sheet thicknesses in one partExercise 18 Multi-body technique. Surface skeleton. Duct TeesExercise 19 Solid – Surface – Sheet Metal. The CasingExercise 20 The flat pattern of the stamped sink. Unwrap